Ovens

Ovens, also known as drying stoves, are devices used to dry and sterilize glass and metal containers used in various laboratory processes. The laboratory stoves allow to carry out the sterilization by dry heat, where hot air is used to carry out this process, these equipments allow a uniform distribution of heat inside, where the material is exposed to temperatures of approximately 170ºC for 2 hours.

Dry heat sterilization works by destroying microorganisms by oxidation of their cellular components. This is a less efficient process than wet heat sterilization because microorganisms die more quickly when in the presence of water because it allows their protein configuration to be altered more easily and provides a means of evenly distributing heat throughout the sterilizing equipment's internal chamber. For this reason, to achieve the sterilization of the material using dry heat, higher temperatures should be applied for a longer time.

Types of Laboratory Ovens a Laboratory May Need

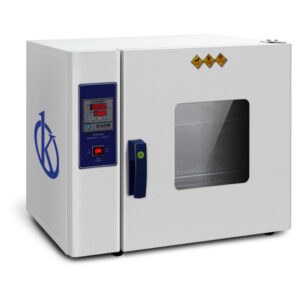

Drying Ovens

Smart microcomputer PID control, precision LED display temperature control, timing, overheating alarm, Rs 485 computer interface, internal stainless steel mirror, anti-acid, anti-corrosion; hot air circulation system and maintenance. Widely used for drying, sterilization, thermostatic storage, heat treatment and other fields. Suitable for a user of higher temperature uniformity requirements. The basis of the laboratory research units supporting the equipment, the recommended use for the intermediate and superior laboratory.

Widely used in the drying process, sterilization, thermostatic storage, heat treatment, other fields, basic equipment of laboratory and research units, but not for volatile, flammable, explosive and other items, to avoid causing an explosion.

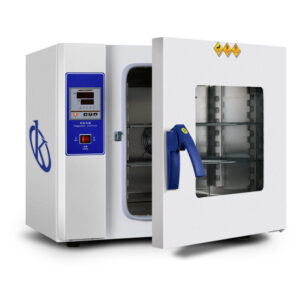

Industrial Oven

Smart temperature control by microcomputer, digital display; centrifugal wind wheel, heat flow uniformly; large study space, fast heating time; (can be equipped with anti-deflagrant locks, anti-deflagrant doors). Used for dehydration and drying of the product, suitable for industrial, mining, batch production in workshops, can be an uninterrupted operation for a long time. Widely used in electroplating industry, electronics industry, oil alloy jewelry drops, food and plastic industry, leather industry, hardware industry, etc. It is not suitable for processing flammable and explosive materials.

For dehydration, drying, producing industries such as electroplating industry, electronics industry, alloy jewelry drip, food, plastics industry, leather industry, hardware and other applications, but not for strong volatiles. Flammable articles and explosives to prevent explosions. (If you meet explosion-proof requirements, you must install security facilities, such as explosion-proof locks and armored doors.)

In Kalstein you can find the Ideal Oven for your Laboratory

Electric heating drying oven

Microcomputer intelligent PID control, precision LED display temperature control, timing, over-temperature alarm, RS 485 computer interface, mirror stainless...

Double Door Industrial Air Drying Oven

Double layer door; Microcomputer intelligent temperature control, digital display; centrifugal wind wheel, heat flow evenly...

Single Door Industrial Air Drying Oven

Microcomputer intelligent temperature control, digital display; centrifugal wind wheel, heat flow evenly; large studio space...

Electric heating drying oven

Micro-computer intelligent control, temperature control, timing, over-temperature alarm function; fan forced convection hot air circulation system; stainless steel liner/optional...

Our Best Selling Oven

Vacuum drying furnace widely used in biochemistry, chemistry, pharmaceutical, health care, agricultural research, environmental protection and other research applications for drying and roasting powder as well as disinfection and sterilization of glass containers used. Particularly suitable for the drying of heat sensitive, easily decomposable and complex composition articles of easily oxidized materials for quick and efficient drying. A variety of complex mechanical components or other porous samples after cleaning by a vacuum-drying method are completely dried without leaving any residual material.

Widely used in biochemistry, chemistry, pharmaceutical, medical care, agricultural research, environmental protection and other research applications for drying and roasting powder as well as disinfection and sterilization of glass containers used. Particularly suitable for the drying of heat sensitive, easily decomposable and complex composition articles of easily oxidized materials for quick and efficient drying.

| Model | YR05260 (A) | YR05262 (SS) | YR05261 (A) | YR05263 (SS) | YR05264 (A) | YR05265 (SS) |

| Supply Voltage | 220 | |||||

| Temp. Range (°C) | RT + 5 ~ 250 | |||||

| Timer Range | 0 ~ 999 min | |||||

| Material | Zinc Plating Chamber | Stainless Steel | Zinc Plating Chamber | Stainless Steel | Zinc Plating Chamber | Stainless Steel |

| Temp. Accuracy | ± 1 | |||||

| Temp. Fluctuation (%) | ± 2 | |||||

| Power (KW) | 0.9 | 1.4 | ||||

| Vacuum Degree | < 133 | |||||

| Inner Size (mm) (H x W x D) | 28 x 30 x 30 | 40 x 41.5 x 35 | 44 x 48.5 x 42.5 | |||

Analysis of the best Ovens for your Laboratory

Main differences between a laboratory Ovens and a laboratory incubator

Among the great variety of equipment needed to carry out the...

How does a natural convection Ovens work?

A laboratory stove by natural convection is one that extracts air from the environment in which the stove is located...

Laboratory Ovens, which to choose?

Among the great variety of equipment needed to carry out the many activities of a laboratory, we can highlight...

Types of laboratory Ovens

The laboratory stove or drying stove is equipment used to dry and sterilize glass and metal containers in a laboratory. It is also known as a drying oven...

Catalog of models of Ovens on offer

-

Vacuum Drying Oven YR05265-1 (SS) // YR05995 (S)

Select options This product has multiple variants. The options may be chosen on the product page -

Double Door Industrial Air Drying Oven YR05257-1 // YR05259-1

Select options This product has multiple variants. The options may be chosen on the product page -

Vacuum drying oven YR05260 (A) // YR05261 (A) // YR05264 (A)

Select options This product has multiple variants. The options may be chosen on the product page -

Single Door Industrial Air Drying Oven YR05256 // YR05258

Select options This product has multiple variants. The options may be chosen on the product page

Guides to become an expert in Ovens

What’s the use of a Laboratory Ovens?

The laboratory stove is an instrument used to dry and sterilize glass containers, which come from a laboratory wash...

Considerations when using a Oven

The drying stove is a device used to dry and sterilize glass and metal containers in the laboratory. It is also identified by...

Drying Oven, from simple to complex

The drying stove is a device used to dry and sterilize glass and metal containers in the laboratory. It is also...

Ovens: dry heat sterilization

Hot air is one of the most commonly used dry heat sterilization methods. This process is carried out in the stoves, which allow the uniform distribution of heat inside, where the material is exposed...

Frequently asked questions about Ovens from our customers

How to know the prices of Ovens?

To know the price of the Stoves we invite you to send us an email with your request through the contact form.

What are the delivery times of the Ovens?

The delivery time of your Kalstein product will depend on the following:

- If the equipment of your interest is in stock or if it must be manufactured.

- The type of freight you have chosen, this may be; air or sea.

- Equipment in stock:

- Delivery Time (Air): 15-30 days.

- Delivery Time (Maritime): 45-60 days.

- Equipment not in stock:

- Delivery Time (Air): 30-60 days.

- Delivery Time (Maritime): 60-90 days.

How to make a purchase of Ovens?

You can make your purchase through:

- By email: [email protected]

- By telephone: +33 (0) 1 78 95 87 02

- E-commerce: Via Kalstein's official website in your country.

How does the warranty work?

At Kalstein, we provide our customers with induction and technical support through new online methods. You can visit our induction videos, technical assistance and guidance provided by a Kalstein team through our YouTube channel (Kalstein English). HERE

Can I request a quote online?

Of course, you can request a quote for the Kalstein team of your interest, directly from our official website. Once you have identified your preferred model, click HERE