Homogenizer

The word homogenize refers to the ability to make a mixture homogeneous, the latter referring to uniformity. This is usually related to the use of chemicals, which are mixed through physical means, until it results in a uniform solution. Homogenization is a technique that is used in many fields, from biology, agriculture and chemistry, to gastronomy, to name a few disciplines, however, are many more.

The term homogenization, used in many fields of science, refers to the process through which a mixture is achieved to have the same properties, i.e., to be uniform and not divided by phases, unlike heterogeneous mixtures. The advantage of homogenizing substances is that it is easier to study the components of the mixture and, in the case of the food industry, provides an increase in quality to the final product.

Types of Homogenizers a Laboratory may need

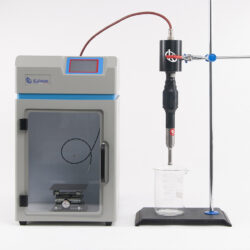

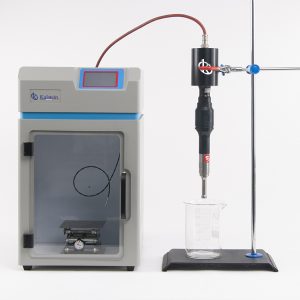

Ultrasonic Homogenizer

Ultrasonic homogenizers are powerful equipment for the homogenization of solid-liquid and liquid-liquid suspensions. Its foundation is based on reducing particles to nano size and distributing them evenly. Ultrasonic homogenizers can be used to mix, disperse and emulsify, resulting in a perfectly homogenized mixture.

Ultrasonic homogenizers are the ideal equipment for reducing particles, both solids and liquids. These devices work as follows: when the sample, which must be moist, is exposed to intense ultrasonation, sound waves pass through the liquid generating cycles of variant pressure, between high and low. When the sample is exposed to low pressure, small vacuum bubbles form. Later, in the high-pressure cycle, the bubbles collapse, resulting in high pressures and high-speed liquid jets. The result of all this process is the production of very small, uniformly distributed particles, i.e. a homogeneous solution.

Handheld Sonicator- Portable Ultrasonic Processor Homogenizer

Ultrasonic Processor is a multi-functional and multi-purpose instrument that uses the ultrasonic to generate cavitation effect in liquid and ultrasonically treats the material. It is equipped with a fully digital intelligent ultrasonic generator, which greatly improves the instrument work,Stability and reliability. The instrument can be used for the crushing of various animal and plant cells and virus cells, and can be used for emulsification, separation, homogenization, extraction, defoaming, washing and accelerating chemical reactions. It is widely used in biochemistry, microbiology, medicinal chemistry, surface chemistry, physics, zoology and other fields.

- Drug extraction, cell, bacteria, and viral tissue disruption. Such as the extraction of cell contents.

- Dispersion, homogenization, and emulsification of the material particles. Such as the dispersion of nanomaterials.

- Accelerate the dissolution and accelerate the chemical reaction. For chemical synthesis, this ultrasonic device is equipped with a soundproof box bracket, a special soundproof box, and a low temperature system.

In Kalstein you can find the Homogenizer ideal for your Laboratory

Electric Ceiling Shaker with Digital Display YR02956

Magnetic stirrers are often used in chemistry and biology. They are preferred over motorized agitator gear...

Digital Intelligent Ultrasonic Homogenizer Processor Sonicator YR05837 // YR05839

Digital intelligent ultrasonic disperser is a kind of ultrasonic equipment used in laboratory...

Ultrasonic Homogenizer YR05832 // YR05836

Ultrasonic processor, also known as ultrasonic disintegrator, ultrasonic homogenizer, ultrasonic cell crusher, ultrasonic nano-material...

Ultrasonic Homogenizer YR05015 // YR05020

Single-chip technology + 4.3-inch TFT capacitive touch screen (optional 7-inch), optional computer communication...

Our best-selling Homogenizer

- Very compact and easy to operate

- Temperature and speed digital display, heating temperature: Rt-380 degrees and mixing speed: 100-1800 RPM

- Heat and corrosion resistant aluminum alloy housing for durability

- Ceramic-coated aluminum heating plate for excellent heat distribution and corrosion resistance

- Specially designed housing prevents spills from damaging electronic components inside

- Secondary thermal insulation board prevents heat loss and eliminates heat damage to electronic components

- Adjustable temperature and rotation speed

| Model | YR02956 |

| Engine power | 100 W |

| Type of motor | Brushless DC motor |

| Motor torque | 450 m N.M |

| Voltage | 220V +/- 10% or 110V +/- 10% |

| Rotation speed of | 60- 1500rpm / 60- 2000rpm |

| Add capacity | 50ml – 50 L |

| Digital screen | LED |

| Add Rod Length | 350mm |

| Remove Rod Material | Stainless steel |

| Length holder | 700mm |

| Chuck voltage range | Ø1,5-10 |

| Product dimension (mm) | 390 x 93x 160 |

| Gross Weight (KG) | 12.1 |

Analysis of the best Homogenizers for your Laboratory

Why are the samples homogenized?

The word homogenize refers to the ability to make a mixture homogeneous, the latter referring to uniformity...

What are the techniques of homogenization?

Homogenization is a chemical technique through which components are constantly mixed that are not miscible...

Use of Homogenizer for dental products

A homogenizer is a vital equipment among the components of any laboratory, since with them the technique of ...

What technology does the homogenizer use?

Homogenizers are indispensable elements in any laboratory, since homogenization is a technique widely used ...

Catalog of Homogenizers models on offer

-

Ultrasonic Homogenizer YR05832 // YR05836

Select options This product has multiple variants. The options may be chosen on the product page -

Ultrasonic Homogenizer YR05015 // YR05020

Select options This product has multiple variants. The options may be chosen on the product page -

Electric Ceiling Shaker with Digital Display YR02956

-

Ultrasonic Homogenizer Processor Sonicator for Liquid Processing YR05829 // YR05831

Select options This product has multiple variants. The options may be chosen on the product page -

Digital Intelligent Ultrasonic Homogenizer Processor Sonicator YR05837 // YR05839

Select options This product has multiple variants. The options may be chosen on the product page

Guides for you to become an expert in Homogenizers

What are the advantages of the Homogenizer?

The word homogenize refers to uniformity, that is, the ability to move a mixture from being formed by several phases ...

How is hydroalcoholic gel made with Homogenizer?

Hydroalcoholic gel, also known as alcohol gel, antibacterial gel disinfectant gel, hydrogel or antibacterial gel, is...

When should the Homogenizer be used?

Homogenization is a chemical technique in which solutes or solvents are constantly mixed, in order to obtain...

Laboratory homogenizer: What are the different types that exist?

These equipments allow obtaining nanoparticles, nano dispersions, nano emulsions and cell rupture at high pressure. It is widely used in laboratories as it facilitates testing with small amounts of sample and ensures quality results; this procedure is a very...

Homogenizer videos in operation

In this section you will find videos of our Homogenizers in operation, packed, receiving service, etc..

Homogenizers in operation

Homogenizers are equipment whose main function is the application of mechanical forces to produce a homogeneous mixture of liquid-liquid or solid-liquid systems. Homogenizers are designed to disintegrate the particles that make up solutes, whether solid or liquid, to form a completely uniform mixture. Pigments, chemicals, foods, plants and cells, among others, can be applied to the homogenization technique.

In the market, these equipment can be found in compact form, for laboratories, and larger, for industries. Despite the number of models available, the most common are: rotor/stator mixers, ultrasonic homogenizers and high pressure homogenizers. The characteristics of each are described below:

- Rotor/stator mixer: these are characterized by having a rotor and a stator. The stator remains stationary and the rotor rotates at high speed. The movement of the rotor within the stator is what creates the suction effect that reduces the particle size of the reagents to be mixed.

Frequently asked questions about Homogenizers from our customers

How to know the prices of Homogenizers?

To know the price of Homogenizers we invite you to send us an email with your request through the contact form..

What are the delivery times of Homogenizers?

- If the equipment of your interest is in stock or if it must be manufactured.

- The type of freight you have chosen, this may be; air or sea.

How to make a purchase of Homogenizers?

- By email: [email protected]

- By telephone: +33 (0) 1 78 95 87 02

- E-commerce: Via Kalstein's official website in your country.

How does the warranty work?

Can I request a quote online?

Of course, you can request a quote for the Kalstein team of your interest, directly from our official website. Once you have identified your preferred model, click HERE