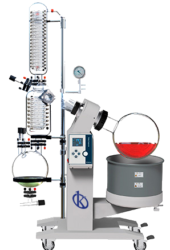

Rotary Evaporators

- A round flask to collect the distilled material.

- A vacuum equipment to reduce the internal pressure of the equipment.

- A height-adjustable column and a spiral condensation column.

- An adjustable heating unit.

- A second round flask for evaporation.

- A pedestal for the rotation motor.

Types of Rotary Evaporator a Laboratory may need

Rotary Evaporator YR02307 // YR02310

Large capacity and large opening of evaporating flask give larger evaporation surface. The evaporating flask keeps rotating when it is constantly...

Rotary Evaporator YR02306

It is suitable for experiment of evaporation, distillation or separation of chemicals. It usually works with water circulating vacuum pump and recirculating chiller ....

Our Best Selling Rotary Evaporator

- Patented technology of double sealing of Teflon(PTFE) AND FV rubber can ensure the negative pressure level.

- Wide power supply range of main machine from 100V to 240V~,50/60Hz.

- PID controller ensures precise temperature control.

- Patented designed structure, the tilt angle of the evaporating flask is adjustable.

- Quick lock button on rotation axis makes it easier to be installed or removed.

- Motorized lift keeps lifting more smoothly.

- Synchronous belt drive mechanism can running smoothly, ultra-low noise during rotation process.

- Individual main machine and water bath design for easy future upgrades.

| Model | YR02306 | |

| Rotaion Speed | 10~280 rpm | |

| Pressure rise rate of vacuum system | <=0.33kPa/min | |

| Temperature Range | RT+5~95℃ | |

| Temperature Stability | ±1℃ | |

| Temperature Control | Keypad input, digital display | |

| Speed Control | Knob setting, digital display | |

| Lifting | Motorized lift | |

| Lifting Distance | 150mm | |

| Lifting Speed | 10mm/s | |

| Rotary Motor Power | 40W | |

| Heating Power | 1300W | |

| Condensing Area | 0.126m2 | |

| Evaporating Flask | 500ml, 1000ml | |

| Receiving Flask | 1000ml | |

| Vacuum Sealing | Double sealing rings made of Teflon+ Viton materials | |

| Water Bath size ·Capacity | 250×130mm·6.5L | |

|

Evaporating Speed

|

Water | 23ml/min |

| Ethanol | 26ml/min | |

|

Power Supply

|

Main Machine | 100V~240V, 50/60Hz |

| Water Bath | 110V~, 60Hz or 220-240V~, 50/60Hz | |

| Ambient temperature | 5~35℃ | |

| Environment Relative Humidity | <=70 | |

| Protection Class of Shell | IP20 | |

| Pollution Prevention Grade | Grade 2 | |

| Dimensions | 595W*390D*680Hmm | |

|

Net Weight

|

Main Machine | 10KG |

| Water Bath | 3.9KG | |

Catalog of models of Rotary Evaporators on offer

-

Rotary Evaporator YR02306

-

Rotary Evaporator YR02307 // YR02310

Select options This product has multiple variants. The options may be chosen on the product page -

Water Circulating Vacuum Pump YR05158

Guides to become an expert in

Rotary Evaporators

Rotavapor why is it fundamental in a Laboratory? - Laboratory

A wide variety of examinations, experiments and endless chemical, medical and biological procedures are carried out in...

What is the usefulness of a Rotavaporador? - Laboratory

A Rotavaporador is an equipment that in general has different uses in laboratories and other areas of application...

Organic chemistry:How do you operate a Rotary Evaporators?

Organic chemistry is the branch of chemistry that is responsible for the study of the structure, properties, synthesis...

Advantages and Disadvantages of using a Rotary Evaporator?

A Rotary evaporator is a laboratory equipment, applied in the chemical sector, capable of separating or rescuing substances at very low pressures, to extract from them the various elements that compose it, through distillation processes, and to be able to separate the components from each other.....

Videos of Rotavapor in operation

In this section you can find, our Rotavapores in operation, packaged, receiving service, etc..

Rotavapor Assembly

A rotary evaporator is composed of an electric motor that causes the rotation of a tube attached to a ground glass joint guide tube. The latter has a round-bottomed flask containing the solution attached to its structure. Maintaining a rotating motion, this flask is partially immersed in water. The system contains a refrigerant that circulates a liquid (water or antifreeze), this generates the condensation of the solvent, which is recovered in a collector. Its components include:

- A round flask to collect the distilled material.

- A vacuum equipment to reduce the internal pressure of the equipment.

- A height-adjustable column and a spiral condensation column.

- An adjustable heating unit.

Frequently Asked Questions about Rotary Evaporators

How to know the prices of Rotary Evaporators?

To know the price of Rotavapores we invite you to send us an email with your request through the contact form.

What are the delivery times of the Rotary Evaporators?

- If the equipment of your interest is in stock or if it must be manufactured.

- The type of freight you have chosen may be either air or sea.

How to make a purchase of Rotary Evaporators?

You can purchase through:

- By email: [email protected]

- By telephone: +33 (0) 1 78 95 87 02

- E-commerce: Via Kalstein's official website in your country.

How does the warranty work?

At Kalstein, we provide our customers with induction and technical support through new online methods. You can visit our induction videos, technical assistance and guidance provided by a Kalstein team through our YouTube channel (Kalstein English). HERE

Can I request a quote online?

Of course, you can request a quote for the Kalstein team of your interest, directly from our official website. Once you have identified your preferred model, click HERE