The laboratory ovens is an instrument used to dry and sterilize glass containers, which come from a laboratory wash. In other words, this chamber with cavity, which will have a higher temperature than the environment, will remove all moisture from the metal or glass container.

The sterilization that becomes effective inside this ovens is called dry heat and is only done with a temperature of 180 degrees Celsius during the time of 2 hours. The process of this is that glass, when heated, by an air of high temperature, eliminates the possibility that any biological activity is found.

The ovens have different uses within a laboratory, outstanding for use with the glass or metal implements of the laboratory. They are also used to perform manipulation and sterilization work to different biological elements in order to obtain a specific result.

What material are these equipment made of?

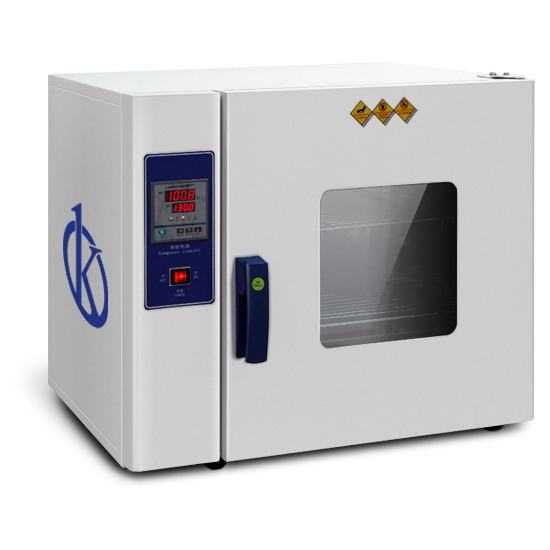

The ovens or drying oven is made inside and outside with stainless steel material, so it has great durability, and thanks to a microprocessor has uniformity in temperature. It is controlled by a digital manual.

What should be considered when choosing a laboratory ovens ?

The laboratory ovens are specially designed with an interior stainless steel chamber, which ensures that they can control temperatures that can range from room temperature to 300°C.

It is also very important to keep in mind that nowadays we can find different types of models, being analog or digital. Usually these furnaces or ovens allow researchers to set the desired temperature and time according to the protocols under which they are working, depending on the type of metal and glass material.

General characteristics of laboratory ovens

Laboratory ovens have a number of characteristics that allow them to differentiate from the rest. To help you choose the one that’s best for you, it’s important to know the general features they offer:

- They can be obtained in different sizes for the realization of different industrial processes.

- They are completely made of stainless steel, thus guaranteeing their durability.

- They are usually composed of an internal camera that has three trays, on which the different instruments are placed.

- They can have an LCD screen to be able to monitor the drying and sterilization process better. They also have buttons and dials to be able to configure them.

Types of ovens according to their application

As we have already indicated, laboratory ovens can have a large number of industrial uses and applications. For example, they can be used for quality control, pharmaceuticals, biotechnology and materials manufacturing. These are some of the most outstanding uses that are given to laboratory ovens depending on their type:

Convection ovens by gravity and forced air: are used to dry samples that have weight before and after drying.

Gravity convection ovens : these are widely used in biological laboratories to eliminate the different microbiological contaminants in the different laboratory instruments used.

High-temperature, high-gravity, vacuum or mechanical convection ovens: These ovens are commonly used in pharmaceutical, forensic and clinic laboratories. HERE

Vacuum ovens : perfect for working with materials that need an inert atmosphere.

Multi-purpose forced air ovens : used for drying and sterilizing metal and glass materials.

At Kalstein we offer you a wide variety of ovens according to your needs. That’s why we invite you to take a look at the “Products” menu. HERE