Homogenization of cosmetics is usually performed in a shaker, which is a device that uses a propeller or a palette to shake the mixture and prevent it from separating. Other homogenization methods, such as ultrasound, can be used, but shaker is the most commonly used method.

Cosmetic homogenization stirrers are generally low speed and low viscosity, and are designed to mix efficiently and in a short time. Most stirrers are made of stainless steel to prevent corrosion, and some are also coated with dust to prevent the mixture from sticking to the stirrer.

Homogenization Processes

The process of homogenization begins with mixing the ingredients in a tank, which is then loaded into the stirrer. The mixture is stirred in the stirrer until completely homogeneous. The stirring time varies depending on the size and composition of the mixture, but usually 30 to 60 minutes are required.

Once the mixture is completely homogenized, it is sent to another tank or containers for storage or sale. The homogenized final product has a more uniform texture and appearance, and is also more stable over time.

The homogenization of cosmetics is an important process to ensure the quality and stability of a final product. The shaker is the most commonly used method to homogenize cosmetics, and other methods such as ultrasound can be used if necessary.

Method of use

The most common methods use a shaker or mixer to force the ingredients to mix. This can be a slow and tedious process, but it is necessary to ensure that products are high quality and consistent. There are two main methods:

- Microemulsion: is a physical method that uses a shaker to force the mixture of ingredients. This helps to dissolve and stop insoluble components in a substance called surfactant. It is an effective method for homogenization, but it can be expensive and requires specialized equipment.

- The ultrahomogenization process is a chemical method that uses an alkaline solution to dissolve insoluble ingredients. This is especially effective for the homogenization of oils and fats. The process of ultrahomogenization is more expensive than microemulsion, but it is faster and does not require specialized equipment.

Homogenization is an important process in the manufacture of cosmetics, as it allows products to be of high quality and consistent. The most common homogenization methods use a shaker or mixer to force the ingredients to mix. This can be a slow and tedious process, but it is necessary to ensure that products are high quality and consistent.

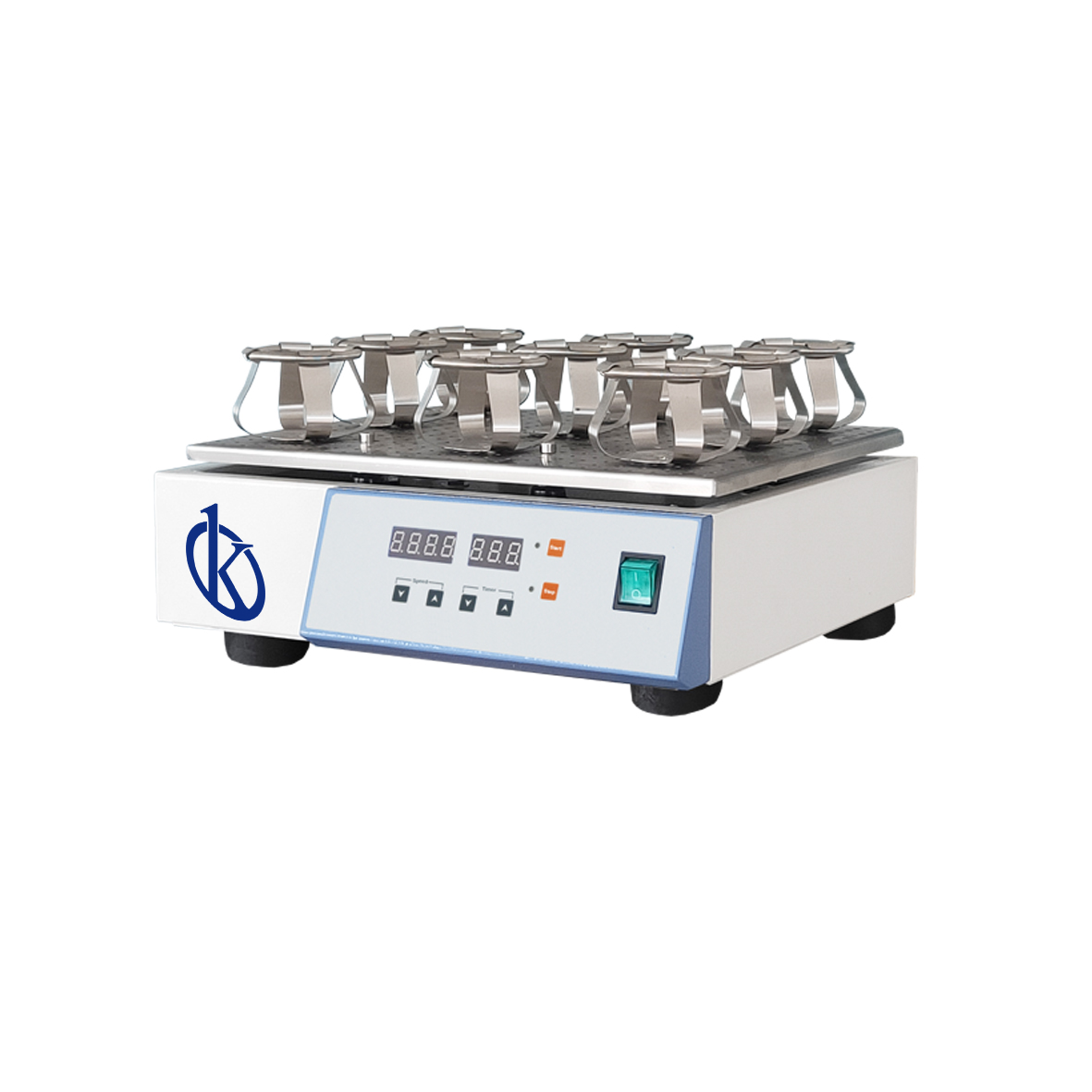

Agitators brand Kalstein

In this category, our users will find the appropriate accessories for all the equipment they want to use. This includes a wide selection of Agitators belonging to the YR series. Which meets certain special features such as: Brushless DC motor, long service life, no maintenance needed; Overcurrent protection function, automatically shuts off power without affecting other equipment; Automatic memory function, after start-up, runs according to the latest configuration. If you need to know more about our range of equipment, we invite you to check our catalog HERE

For more information, we at Kalstein are manufacturers of the best Agitators, and for this we invite you to review our catalog HERE and have the best advice, so that your purchase is the ideal and at favorable prices.